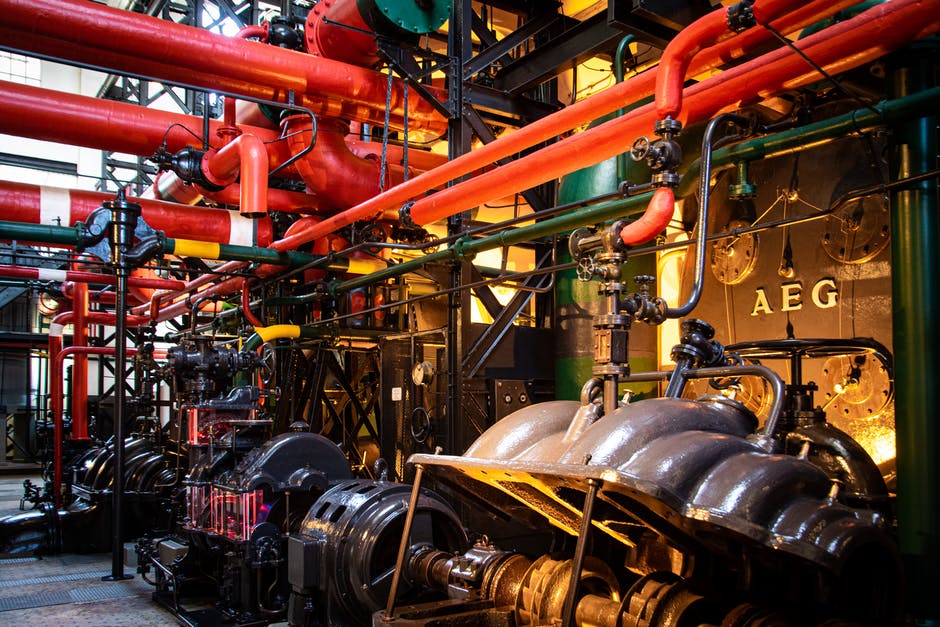

The Importance of Maintenance for Industrial Machines

Any heavy machinery used at a manufacturing business or production site experiences wears and tear over time. About 40% of machinery requires maintenance because of excessive wear.

How can you prevent excessive wear before it affects your productivity? The answer lies in regular maintenance. How can regular maintenance help you and your industrial machines?

Read on to discover the importance of industrial machine maintenance. And how it benefits you. It also benefits your industrial equipment. Here are some tips that’ll make it easier.

The Importance of Regular Maintenance

It is crucial to keep up with the maintenance of industrial machines to keep them running. Without proper industry equipment preservation, machines can break down. It can cause production to halt.

Also, regular maintenance can help prolong the life of heavy equipment. Helping save the company money in the long run. Performing maintenance catches potential problems early on. It fixes them before they become critical issues.

Different Types of Maintenance on Industrial Machines

Industrial machines need regular maintenance to keep them running. The different types of care performed on an industrial machine include.

Preventive Maintenance

Preventive maintenance is critical for industrial machines. It helps to keep them running. By performing regular maintenance, companies can avoid costly downtime and repairs. Preventative maintenance can also extend the life of an industrial machine.

Corrective Maintenance

Corrective maintenance when there is a problem with the equipment that needs fixing. This type of maintenance is critical because it ensures that the machine is running. For instance, if you work in the oil, gas, chemical, or food industry, you know how essential it is to keep this machinery running at its optimum level to ensure that there are no cross-contamination issues. But if something comes loose and particles start flowing into the machine, you know that you have a serious problem. This is where corrective maintenance comes in. You can assess the issue and see what components would be best to stop this from happening again, e.g. you can try a Y strainer to help with the flow and put an end to cross-contamination without having to shut the machine down.

Neglecting corrective maintenance can lead to further problems with the equipment. It can lead to its breakdown.

Predictive Maintenance

Industrial machines are expensive and vital to the operation of many businesses. Maintenance is critical to keep them running.

Predictive maintenance uses data and analytics.

It predicts when a machine is likely to need repairs or replacement. It can help businesses avoid downtime. And keep their industrial equipment in perfect condition.

How to Maintain Your Industrial Machines

Consider a few critical things when maintaining your industrial machines. First, follow the manufacturer’s instructions for care and maintenance.

Second, keep the equipment clean and free of debris. It will help ensure the machine is running and prevent unwanted wear and tear. Finally, regular lubrication of the equipment to keep moving parts working.

It is critical to have manufacturer’s insurance to maintain your industrial machines. It is a type of insurance that helps protect manufacturers from financial losses. These loses came from claims or damages because of their products.

This type of insurance can help to cover the costs of repairs and replacements as you need to ensure that you have fully functioning equipment that can keep your business productive. If you do require replacements, you will need to do your research on what would be best and if you could benefit from other types of machinery. You can find out more here about some machines that can be the right fit. Insurance also takes care of legal fees that you may associate with these claims.

Maintaining Industrial Machines is Important

Proper maintenance of industrial machines is crucial for optimal performance and safety. A well-maintained machine will operate efficiently. They will last longer than one that needs to be well-maintained.

A company that invests in proper maintenance of its industrial machines will ultimately save money and reduce downtime. Remember to browse our site for your industrial suppliers, equipment, and product needs.